Shaft alignment is an absolute requirement for machinery putting it into the services. It is basically a process in which two or more shafts are aligned with each other to within a tolerated margin. Alignment is necessary because misalignment can cause injuries, malfunctions, and accidents.

This shaft positioning depends on certain tools because humans can leave a lot of space for errors and mistakes. Laser alignment systems are one the popular systems that can confirm perfect and faultless tolerances and coupling below the recommended margin.

Moreover, in this alignment process, laser technology is used, which is not a new concept. Laser systems are used to make the shafts aligned properly with perfect precision and reliability.

Furthermore, gyroscope-based systems are also used in this industry that helps in aligning couplings, but these systems are not so accurate and lack perfect precision. In addition, gyroscope based systems are quite challenging to set up. And these systems are not the ideal systems when it comes to preparing remedies quickly.

Besides, misalignment that is experienced by components falls into two different categories. The first category is the angular misalignment in which the shafts lines either are at a vertical angle or horizontal angle as well they can be on the same plane or on a different plane. The best laser technology is used in order to obtain the same result.

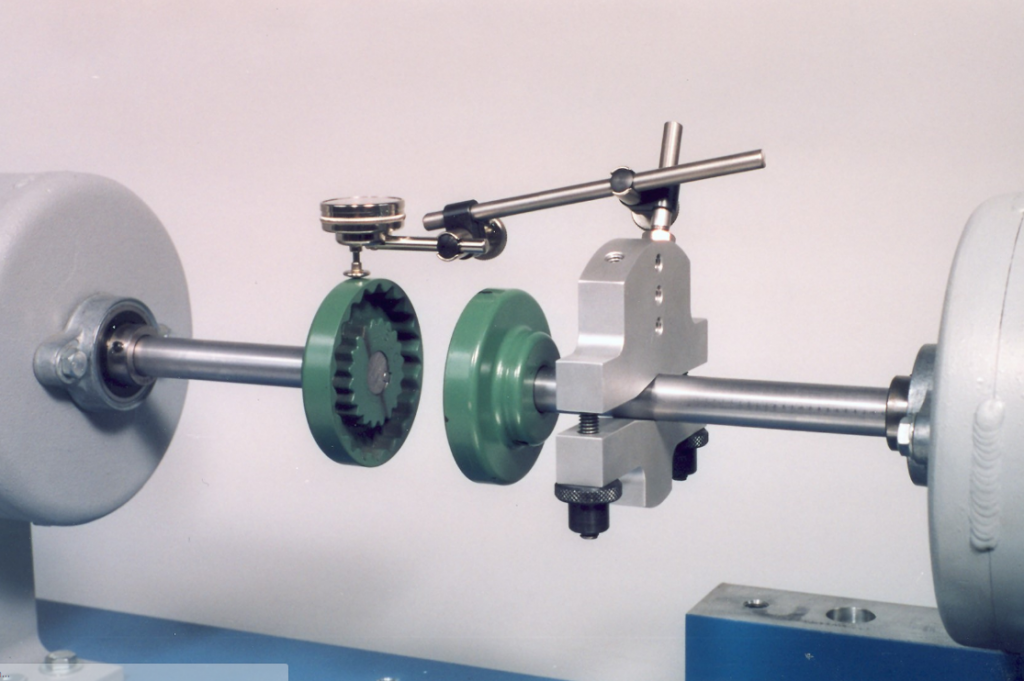

Shaft Alignment

The second category is the parallel misalignment in which the shafts lines are parallel; however, despite parallel lines, these are separated horizontally or vertically. Regardless of what type of misalignment a shaft is experiencing, alignment tools are available here that can help in correcting the error.

As mentioned earlier, laser technology is used to align the shafts. Laser levelling tools use the laser beam and perfectly shoot the straight line with minor tolerances.

The laser technology shaft positioning tools use three main components. The first part is the laser, the second is the sensor, and the third part is an electronic device that is used to calculate the end results of measurements.

The laser component is used to shoot the beam light to the sensor. The electronic device then picks the measurements and displays the recommended adjustments that should be made. This technology is applied to many other components and equipment.

The shaft alignment procedure is very crucial in several industries where machines are used to manufacture various products. And if the machines are not aligned properly, then it will cause potential damages and accidents. For more inforamtion visit our website: